Curable hybrid Point binder system for low temperature flexibility: A Study

Curable hybrid Point binder system for low temperature flexibility: A Study

Exterior architectural coating is one of the coating segments where lots of complexity comes into play in terms of application and its life-related requirements. External coating needs to be performed in different environments, from low to high temperatures, depending on the geography of the location. Most ordinary emulsions used for exterior water-based coatings are of a hard polymer for better surface hardness and strength. However, this characteristic feature draws a disadvantage when the temperature goes down to a limited value, where the polymer chain is unable to resist the pressure of external movement. Low temperature flexibility for architectural coating plays an important role in exterior coating for determining the life of the coating products. This study demonstrates the performance requirement for exterior coating using a combination of products.

Temperature is an environmental factor that directly or indirectly impacts both living and non-living things in different biological and nonbiological processes. Process of degradation of polymer from temperature changes has been reported in many literatures from a crystallization point of view. Polymers containing water-based coatings also deteriorate over time due to temperature changes. Exterior architectural paint is more susceptible to temperature variation compared to interior environments. This exterior temperature variation In India changes differently in each location. Maximum and minimum temperatures recorded till 2022-23 are reported in Table 1. The life of a polymer is greatly impacted due to huge temperature variations. However, the impact from a narrow range of variations is not too much on the polymer if it is designed as per the required glass transition temperature. [1,2,3,4]

Table 1: Temperature at different locations

Location | Max. temperature ℃ | Mini, temperature ℃ | ΔΤ °C |

Bikaner, Rajasthan | 47.1 | - 2 | 49 |

Aya Nagar, Delhi | 44.6 | 3 | 41.6 |

Kolkata, West Bengal | 43.9 | 5 | 38.9 |

Ahmedabad, Gujarat | 44 | 6.7 | 37.3 |

Mumbai, Maharashtra | 41.3 | 24.7 | 16.6 |

Chennai, Tamil Nadu | 42.7 | 28.2 | 14.5 |

These temperature variations impacting exterior paint in terms of its debonding, cracking, flacking due to the polymer- pigment - substrate bonding failure. The low temperature impact on the polymer is more compared to high temperature, as at low temperature, chain movement is reduced and brittleness Imitates the cracking once the deviation of expansion starts between the bonding substrates. A polymer contains crystalline and amorphous phases. It behaves differently under different temperatures. One similar stress-strain graph is reported in the literature that explains this property [5]. Also, due to cold flow, the polymer performance properties change and start to crystallize. This crystallization process continues in the external environment due to heating and cooling cycles. This process continues over the years.

Most of the exterior paint for the Indian subcontinent is formulated to be applied in the range of 20-35 ℃ range which is an ideal range for application to adhere to the substrate and perform. But post applications in exterior environment coating are impacted by the changes of the environment, from high to low temperatures, Low temperature flexibility of the coating is the property that resists debonding, chain breaking at low temperatures. If we consider the Initial bond length Is L=1 mm between two bonding substrates, the difference in linear variation of the two materials would vary with a temperature change. Due to the external dimensional variation of the substrate, below the glass transition temperature of the polymer, chain movement is restricted in the polymer, and pressure is built up in the bonding area. This leads to potential delamination from the substrate.

Table 2: Thermo linear variation

ΔΤ °C | Thermo-plastic linear expansion, nm | Concrete linear expansion, nm | Difference, nm |

5 | 1.001 | 1.00005 | 0.00095 |

10 | 1.002 | 1.0001 | 0.0019 |

20 | 1.004 | 1.0002 | 0.0038 |

30 | 1.006 | 1.0003 | 0.0038 |

40 | 1.008 | 1.0004 | 0.0076 |

Many attempts were reported elsewhere to compensate for this problem in water-based exterior coating segments. One most common approaches is a two-part system, one produces flexibility, and another produces hardness of the system. A flexible polymer-based system is used as a base coat and a hard polymer coating as a topcoat. The second approach is a one-part core-shell structured polymer-based coating with a combination of hard and soft polymers. The third approach is inherent flexibility with a modified acrylic hybrid polymer as a single coat. The fourth approach is the self-curable two different polymer latex-based base coat and topcoat. The fifth conventional approach demonstrates the utilization of a plasticizer molecule to improve this characteristic. In the exterior environment, this technique has a limited advantage due to the migration phenomenon. However, this approach potentially solves the requirement if the plasticizer is preferentially soluble in the acrylic polymer with optimum dosage. Alternatively, this process alters the performance requirement in high-temperature situations. In self-curable technology, a water-based polymer participates in the formation of post-film formation bonding to convert its structure from thermoplastic to thermoset type structure.

The present design demonstrates the use of an active topcoat with a base coat combination and its life span prediction to perform in an exterior environment. Newly designed polymer Bondex D 4823 is demonstrated against a conventional high-performance exterior binder (CFPEB). Performance properties of the base coat are demonstrated with three lab-designed polymers (Expt. A, B, C]. Physical properties of binders are shown in Table 4.

Table-4

Test Parameters | Topcoat -

| Base coat

| |||

Bondex D 4823 | CHPEB | Expt. A | Expt. B | Expt. C | |

Appearance | Milky white | Milky white | Milky white | Milky white | Milky white |

% Solids by weight @110 ℃ for 1 hr. | 49 | 49 | 49.2 | 49.1 | 49.9 |

Viscosity at 3ºC, poise (Brookfield RVT Spindle 2, 20 rpm) | 1 | 8 | 8 | 8.96 | 9.28 |

PH at 30 ℃ | 7.5 | 7.5 | 8.99 | 8.99 | 8.99 |

Avg. PSD in nm | 120 | 117 | 120 | 117 | 178 |

MFFT in ℃ | 27 | 27 | 24 | 9 | 0 |

FTIR | Pure acrylic | Pure acrylic | Styrene acrylic | Styrene acrylic | Styrene acrylic |

The initial exterior paint study is demonstrated in low PVC paint in Table 5.

Table-5

Properties | Topcoat | Base coat | |||

D 4823 | CHPEB | Expt. A | Expt. B | Expt. C | |

1) Color | White | White | White | White | White |

2) pH | 9.5 | 9.4 | 9.35 | 9.31 | 9.38 |

3) TIO2 Content | 15 | 15 | 15.0 | 15.0 | 15.0 |

4) Binder content | 40 | 40 | 40.0 | 40.0 | 40.0 |

5) Specific Gravity | 1.3 | 1.3 | 1.27 | 1.28 | 1.28 |

6) % Yellowness | 0.618 | 0.705 | - 0.292 | - 0.693 | - 0.513 |

7) % Whiteness | 95.47 | 95.43 | 94.57 | 94.30 | 94.28 |

8) % Brightness | 92.15 | 92.08 | 90.73 | 90.40 | 90.31 |

9) Contrast ratio | 94.92 | 97.33 | 93.25 | 92.54 | 92.55 |

10) Lab DPUR ** | 8 | 8 | NA | NA | NA |

** On a Scale of 10 (Where 20-Excellent, 5-Moderate, and 1-Poor)

Findings:

It was demonstrated that the quality of D4823 as a top coating binder was less compared to the conventional grade of high-performing exterior binder (CHPEB) as shown in panels. There is no visual (by naked eye) cracking observed. Water absorption was found little less.

Table 6 reports after 3 cycles

Properties | Topcoat- D4823 | CHPEB |

Cracking | 10 | 10 |

Water marks | 8 | 8 |

Water absorption | 8 | 7 |

Adhesion Cross Cut (1 mm/ 0.5 mm) | 9 | 5 |

Gloss- 20/ 60 / 85 | 22/60/80 | 15/58/81 |

** On a Scale of 10 (Where 10=Excellent, 5=Moderate, and 1=Poor)

A cross-cut adhesion test was conducted after the immersion cycles. There is a drastic difference compared to the CHPEB grade. Tendency of delamination from the substrate after crosscut with 1 mm & 2 mm blades.

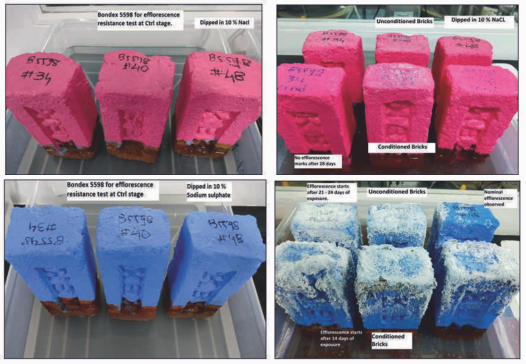

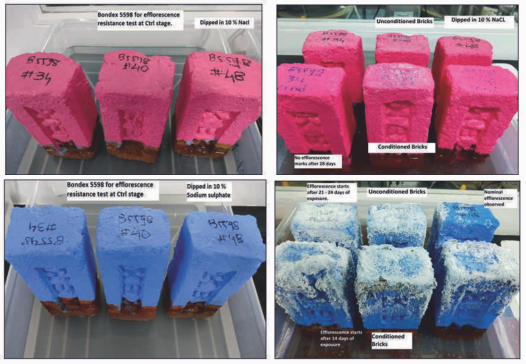

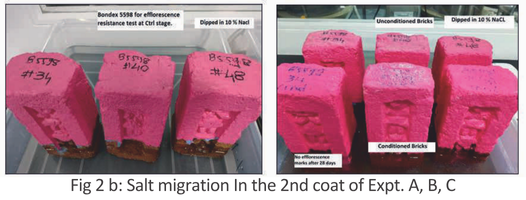

Salt migration from concrete through the coating has the possibility of creating some pressure on the coating film. Post swelling of the paint film, this will migrate and be deposited on the outer surface. This salt formation also alters the initial appearance of the coating. Alternatively, the ability to resist this process allows the base coat polymer to protect the exposure of topcoat to this. Three designs of styrene acrylic are demonstrated as base coat binders for this proposed system. Out of these, the best performance is demonstrated with grade c. It is also need to establish at what thickness this coating suitably performs. Two coats of these grades performed better as compared to a single coat (shown fig 2a & 2b). This resistance was assessed after 2 and 4 weeks of exposure to salt solution. Figure 2b shows the ability of the coating to block the salt migration and maintain good adhesion to the substrate. This indicates better protection at the interface delamination under high osmotic pressure.

.png)

Impact on flexibility:

Many test methods are available to determine the flexibility of material after exposure (Table 7). However, some test methods require a special substrate to check its performance. Limited test methods are available that demonstrate continuous exposure and monitoring of its flexibility. The mandrel bending test is a visual observation that limits the fine cracking determination. Using DMA, one can generate the environment for some period of time and then measure the value. In the Indian environment, exterior coating needs to check flexibility up to 5°C and its retention after cycles of different exposure.

Table-7

Test method | Scope |

ASTM C C754 | This test evaluates the flexibility of artificially weathered latex sealants in a low-temperature environment |

ASTM D2136 | This test method evaluates the ability of coated fabrics to withstand a prescribed bend at an established low temperature. |

ASTM D 1053 | Standard test methods for rubber property stiffening at low temperatures: Flexible polymers and coated fabrics |

ASTM D6083 | Standard Specification for liquid-applied acrylic coating used in roofing, the product needs to pass a 1/2 Mandrel Bend @ - 15 F after accelerated weathering. |

ASTM D412 | Determine tensile properties at room temperature |

ASTM D 522 | This test method is for the mandrel bend test of the attached organic coating |

ASTM C 1305 | Crack bridging ability of liquid-applied waterproofing membrane |

ASTM D 638 | Determine tensile properties at room temperature |

DMA- analysis | Stiffness, elastic /loss modulus at different temperatures |

Base coat flexibility was evaluated as per ASTM D 412 @ 500 mm/min at 25 ℃ and this is reported in table 8. By changing of side chain bulky group in the styrene-acrylic polymer % of coil formation increases and that contribute flexibility. Inherent nature of this polymer retains is characterises performance underneath of the coating for longer duration through protection of specially designed top coat D4823. Whenever there is a process of cracking or delamination forces impacting the whole coating system, these kinds of polymer preferentially contribute to release by dissipating in the form of heat energy and hence protect the top coat further.

Table 8

Flexibility of the base coat

| |||||

Sr.no

| Parameters

| Unit

| Expt. A

| Expt. B

| Expt. C

|

1 | DFT | mm | 0.5 | 0.5 | 0.5 |

2 | Tensile strength | MPa | 2.35 | 0.028 | 0.024 |

3 | % Elongation at break (25 ℃) | % | 267 | 1634 | 2110 |

In regions where the lowest temperature frequently goes beyond certain limits, this hybrid combination of topcoat/ base coat can perform for a longer duration of time. Curable chemistries, as internally attached or post addition, can interlink the two systems at the interface. This chemistry is designed to perform in a controlled manner to exhibit dual character for surface and underneath coating properties.