SUSTAINABLE CHEMISTRIES BASED ON CNSL TECHNOLOGY.

SUSTAINABLE CHEMISTRIES BASED ON CNSL TECHNOLOGY.

INTRODUCTION:

Cardolite

is a global leader in developing renewable, high performance materials derived

from cashew nutshell liquid (CNSL), a non-food, bio-based raw material. With

decades of expertise in CNSL chemistry, Cardolite has pioneered a range of

technologies that offer sustainable alternatives to petroleum- based systems

across coatings, adhesives, composites, foams, and friction materials.

At the core

of Cardolite's innovation are its CNSL-based curing agents, diluents, polyols,

and modifiers. Products made with CNSL technology provide fast curing, corrosion

protection, and excellent low-temperature performance for epoxy coatings

without compromising on sustainability. Cardolite also offers CNSL-based

polyols and diols for high-bio-content polyurethane systems, supporting greener

foam and adhesive technologies.

Through advancements

like Ultra LITE and hydrogenated CNSL derivatives, Cardolite has expanded the

aesthetic and functional versatility of bio-based materials, offering lighter

color, enhanced UV resistance, and lower VOCs. These solutions not only improve

environmental performance but also meet demanding industrial requirements.

With

production and R&D centers worldwide, Cardolite continues to drive the

transition toward circular, low-carbon material solutions supporting the

growing global demand for sustainable chemistry. This article emphasises on the

novel phenalkamide technology.

RESULTS

AND DISCUSSION:

Basic

properties of Phenalkamide Curing Agents:

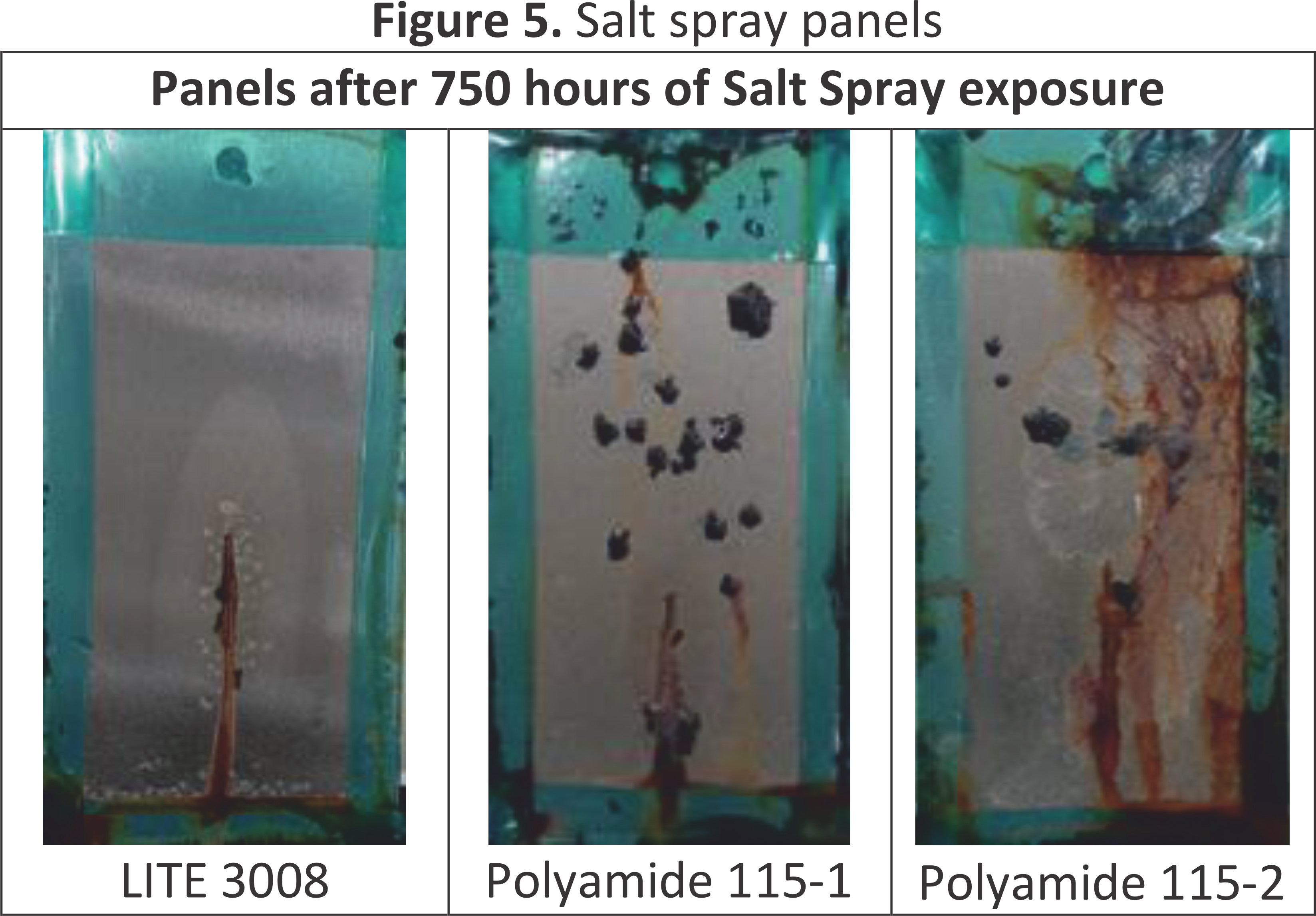

Phenalkamides

are a next-generation class of epoxy curing agents developed by Cardolite. They

are engineered by chemically merging the properties of phenalkamines and polyamides,

creating a hybrid that delivers enhanced performance with broader applicability.

Key Features & Benefits:

· Fast curing and excellent

low-temperature performance, similar to phenalkamines.

· Superior, anti-corrosion and

adhesion capabilities, with strong colour stability and overcoatability.

· Light-coloured formulations,

improving aesthetics and easier application in various conditions.

Advantages

for Coatings and Adhesives:

· Eliminates the need for separate

'summer' and 'winter' converter packages by offering all season versatility and

a wider formulation window.

· The solvent free, low VOC grade offers low viscosity, excellent compatibility with common epoxies (Bis-A, Bis-F), and no induction time required making it optimization friendly for formulators.

· Ideal for universal use systems

across marine, industrial, transportation, and flooring applications, with high

adhesion, fast cure, and robust corrosion protection.

.png)

LITE

3008: A CHAMPION PHENALKAMIDE

Cardolite

LITE 3008 is a specially formulated phenalkamide epoxy curing agent

specifically designed as a cost effective alternative to traditional high

molecular weight polyamide curing agents. It is well suited for both coating

and adhesive applications.

.png)

LITE 3008

provides faster cure even at low temperature compared to conventional polyamide

samples, which favours quicker project completion, reduced downtime, and

earlier return to service while maintaining good film properties. The key

benefits are as follows-

· Quick return to service - Equipment, floors, or structures

can be used sooner.

· Reduced contamination risk - Less time for dust, insects, or

debris to settle on the wet film.

· Weather resistance - In field jobs, protection against

rain, dew, and humidity kicks in quickly.

· Short recoat windows – Multiple coats can be applied in a

single shift.

.png)

A clear and

non-blush film ensures the coating cures to a smooth, defect-free finish with strong

intercoat adhesion, consistent appearance, and long-term durability –

especially critical for marine, protective, and decorative coatings applied in

challenging conditions (Figure 3). Non-blush curing agents perform well even in

high humidity or low temperature, avoiding moisture-induced defects.

.png)

Pendulum

hardness is a useful method to assess the development of crosslink density and the

coating's ability to resist scuffing during the early cure stage, as the

measurement also reflects the material's resistance to small scale deformation.

Results depicted in Figure 4 indicate a similar trend observed with linear dry

times.

.png)

Interestingly, despite faster curing and hardness development due to rapid crosslinking, the cured system retains flexibility comparable to polyamide-cured systems - a distinctive advantage of Phenalkamide technology (Table 3).

.png)

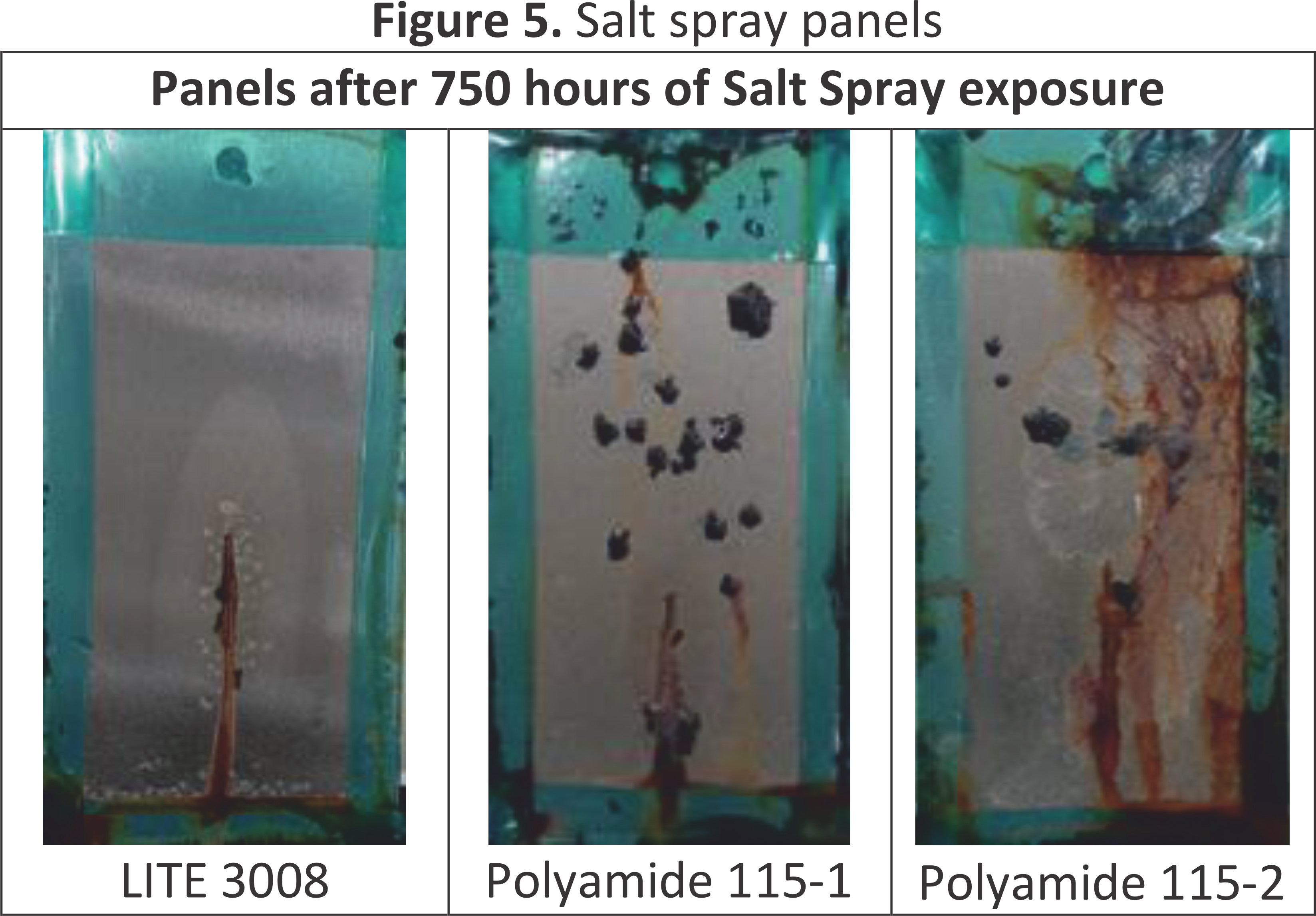

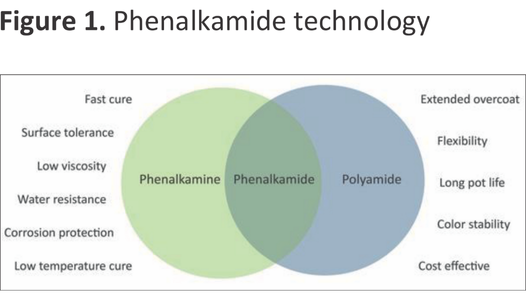

Furthermore,

the long-term corrosion protection performance of the curing agent was evaluated

using salt spray tests. Test panels were prepared at low to medium film thicknesses

and exposed in a salt spray chamber. LITE 3008 demonstrated excellent corrosion

resistance compared to standard Polyamide 115 samples. Notably, these panels were

formulated without any anti-corrosion pigments. The outstanding protective properties

of LITE 3008 can be attributed to the unique structural features derived from

its CNSL component- particularly its inherent hydrophobicity and exceptional

adhesion to the substrate.

.png)

Chemical

resistance enables a protective coating to maintain its barrier properties,

structural integrity, and performance when exposed to harsh chemicals ensuring

safety, durability, and cost efficiency. Phenalkamides generally exhibit

superior chemical resistance compared to their polyamide counterparts,

primarily due to the aromatic ring in the structural backbone derived from

cardanol (Figure 6).

.png)

LITE

3008 advantages in a nutshell -

CONCLUSION:

Cardolite's

innovative technologies, rooted in the unique chemistry of cashew nut shell

liquid (CNSL), deliver sustainable, high-performance solutions for the

coatings, adhesives, and composites industries. By combining bio-renewable

feedstocks with advanced formulation expertise, Cardolite offers products that

meet stringent environmental regulations while enhancing durability, chemical

resistance, and application versatility. From phenalkamide curing agents to

specialized epoxy modifiers and surfactants, Cardolite's portfolio exemplifies the

balance between sustainability and performance, enabling formulators worldwide

to create next-generation systems that are safer, more efficient, and environmentally

responsible.